-

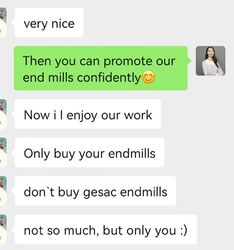

Customer BNow I enjoy our work. Only buy your end mills. Not so much, but only you.

Customer BNow I enjoy our work. Only buy your end mills. Not so much, but only you. -

Customer RToday I tested 50HRC 3 flutes end mill for aluminum. It was very very good. Cuts very good. It barely makes a sound.If you stop watching the machine, you cannot say it is cutting.

Customer RToday I tested 50HRC 3 flutes end mill for aluminum. It was very very good. Cuts very good. It barely makes a sound.If you stop watching the machine, you cannot say it is cutting.

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Processing Object | Metal | Application | Aluminum Alloy |

|---|---|---|---|

| Number Of Flutes | 4 | Helix Angle | 30° |

| Shank Diameter | 6mm | Cutting Diameter | 6mm |

| Coating | TiAlN | Cutting Length | 50mm |

Product Description:

Solid Carbide End Mill is a cutting tool used to mill materials such as aluminum alloy. It is constructed of a 4 flute and has a cutting length of 50mm, creating an ultra-smooth surface with a Ra0.2 finish. It has a shank diameter of 6mm and is suitable for a variety of applications. This particular type of carbide end mill can be found in a variety of shapes, including flat end mill, corner radius end mill, and ball nose end mill.

Solid Carbide End Mill is an ideal choice for milling aluminum alloy, as it can easily cut through the material while achieving a precision finish. It is constructed with a variety of shapes, allowing it to be used for a variety of applications. It is highly durable and reliable, making it a great choice for aluminum alloy machining.

In conclusion, Solid Carbide End Mill is an ideal tool for milling aluminum alloy. It is constructed of a 4 flute and has a cutting length of 50mm, creating an ultra-smooth surface with a Ra0.2 finish. It has a shank diameter of 6mm and is available in a variety of shapes, including flat end mill, corner radius end mill, and ball nose end mill. This type of end mill is highly durable and reliable, making it a great choice for aluminum alloy machining.

Features:

- Product Name: Solid Carbide End Mill

- Material: Carbide

- Tolerance: ±0.01mm

- Coating: TiAlN

- Cutting Length: 50mm

- Carbide Corner Radius End Mill

- Carbide Metal Cutting Tools

- Carbide Flat End Mill

Technical Parameters:

| Attribute | Value |

|---|---|

| Product Name | Solid Carbide End Mill |

| Cutting Diameter | 6mm |

| Application | Aluminum Alloy |

| Helix Angle | 30° |

| Coating | TiAlN |

| Cutting Length | 50mm |

| Shank Diameter | 6mm |

| Processing Object | Metal |

| Flute | 4 |

| Overall Length | 100mm |

| Carbide Ball Nose End Mills | Yes |

| Carbide Corner Radius End Mill | Yes |

| Carbide Metal Cutting Tools | Yes |

Applications:

Solid Carbide End Mill is a type of carbide tipped milling cutters that are specially designed for metal cutting applications. This type of end mill is made from ultra-hard tungsten carbide, with a 4 flute design and a 30° helix angle. It is coated with a TiAlN coating, providing superior hardness, toughness and wear resistance. This end mill is also suitable for high speed machining and can be used to produce precise cutting edges and smooth surfaces on a wide range of metals. It is ideal for use in precision engineering, automotive, aerospace, and medical industries, as well as for general purpose machining and hobby applications. Solid Carbide End Mill is the perfect choice for producing precise, high-quality, cost-effective metal cutting tools with a long service life.

Customization:

Our customized solid carbide end mill is specifically designed for metal cutting applications. It features a helix angle of 30°, 4 flutes, a 6mm shank diameter and an overall length of 100mm. It has a square end cutting edge type and is made of high-quality carbide material.

Our highly durable solid carbide end mill is the perfect choice for precision machining of metals and other hard materials. It is also ideal for a wide range of tasks, such as creating intricate shapes, cutting complex profiles and finishing surfaces with high accuracy.

Whether you need a carbide ball nose end mill or a carbide flat end mill, we have the perfect solution for you. We offer a wide range of carbide metal cutting tools that are designed to meet the highest quality standards.

Packing and Shipping:

Packaging and Shipping for Solid Carbide End Mill:

- The solid carbide end mill will be carefully packed with a protective plastic wrap.

- The package will be sealed to ensure the safety of the product during transport.

- The package will be shipped via a reputable shipping company.

FAQ:

- Q: What is a Solid Carbide End Mill?

A: A Solid Carbide End Mill is a type of tool typically used in milling machines or machining centers to produce intricate shapes and holes. It has a solid carbide construction which provides a high level of hardness and resistance to wear and abrasion. - Q: What are the benefits of Solid Carbide End Mill?

A: Benefits of Solid Carbide End Mill include increased cutting speed, longer tool life, superior surface finish, higher accuracy, and improved productivity. - Q: How can Solid Carbide End Mill be used?

A: Solid Carbide End Mill can be used to produce intricate shapes and holes in various materials such as aluminum, steel, and plastics. - Q: What types of Solid Carbide End Mills are available?

A: Different types of Solid Carbide End Mills are available such as 2-flute, 4-flute, and 6-flute end mills with various cutting diameters and lengths. - Q: What is the cutting speed of Solid Carbide End Mill?

A: The cutting speed of Solid Carbide End Mill depends on the material, number of flutes, and the size of the end mill. Generally, the cutting speed is higher with fewer flutes and larger diameters.